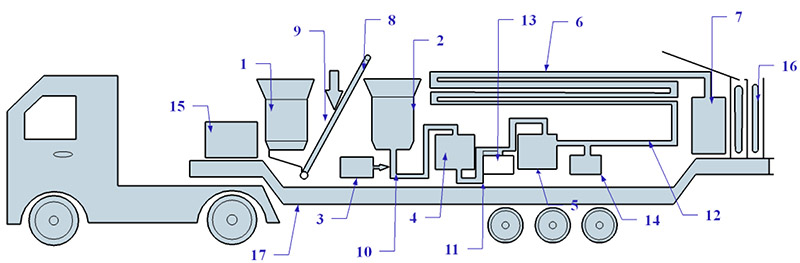

Mobile tire processing unit

Representative No: : EP15173101

Type of IP: Patent

Industry: Industrial Machining

Outline

The present invention pertains to a mobile tire processing unit, in particular a mobile tire processing unit that is able to process full tires and to obtain substantially pure rubber from the processed full tires. The object of the present invention is to avoid the drawbacks of the prior art units (environmental pollution, the substantial amount of noise in operation, road congestion) and to provide for an efficient and highly mobile tire processing unit that works at low noise levels.

The mobile tire processing unit comprises a grinder (2) which is adapted to grind first tire pieces or full tires into second tire pieces of a second given size, wherein the second given size is chosen such that the components making up the full tire are substantially disunited following the grinding; an air compressor (3) for providing pressurized air to the mobile tire processing unit at a position downstream of grinder (2); a first separator (4) positioned downstream of the grinder (2) and receiving the pressurized air from the air compressor (3), the first separator (4) being adapted to receive the second tire pieces from the grinder (2) and to separate by means of gravity steel from the second tire pieces; a second separator (5) positioned downstream of the first separator (4) and also receiving pressurized air from the air compressor (3), the second separator (4) being adapted to receive the second tire pieces less the separated steel and to separate by means of gravity textiles from the second tire pieces; magnetic separator (6, 6’) positioned downstream of the second separator (5) and also receiing pressurized air forth the air compressor (3), the magnetic separator (6, 6’) being adapted to receive the second tire pieces less the separated steel and textiles and to retain along the tubing wall thereoff further residual metallic impurities, such that substantially pure rubber is output from the magnetic separator (6, 6’) and adapted to store the substantially pure rubber that is output from the magnetic separator (6, 6’).