2021. July 10.

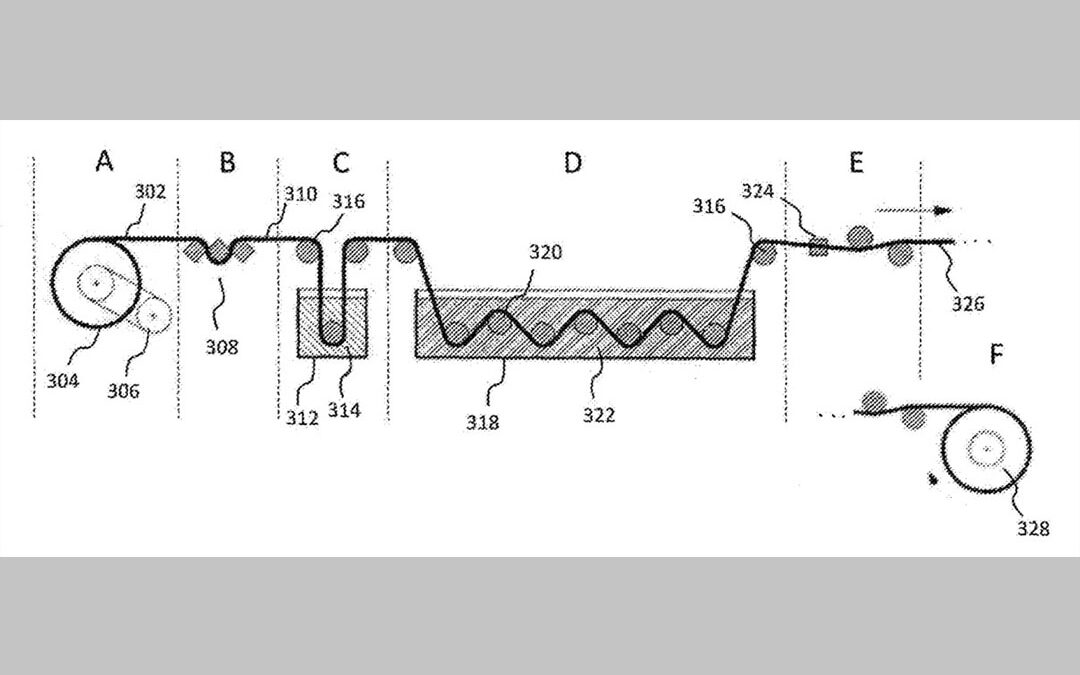

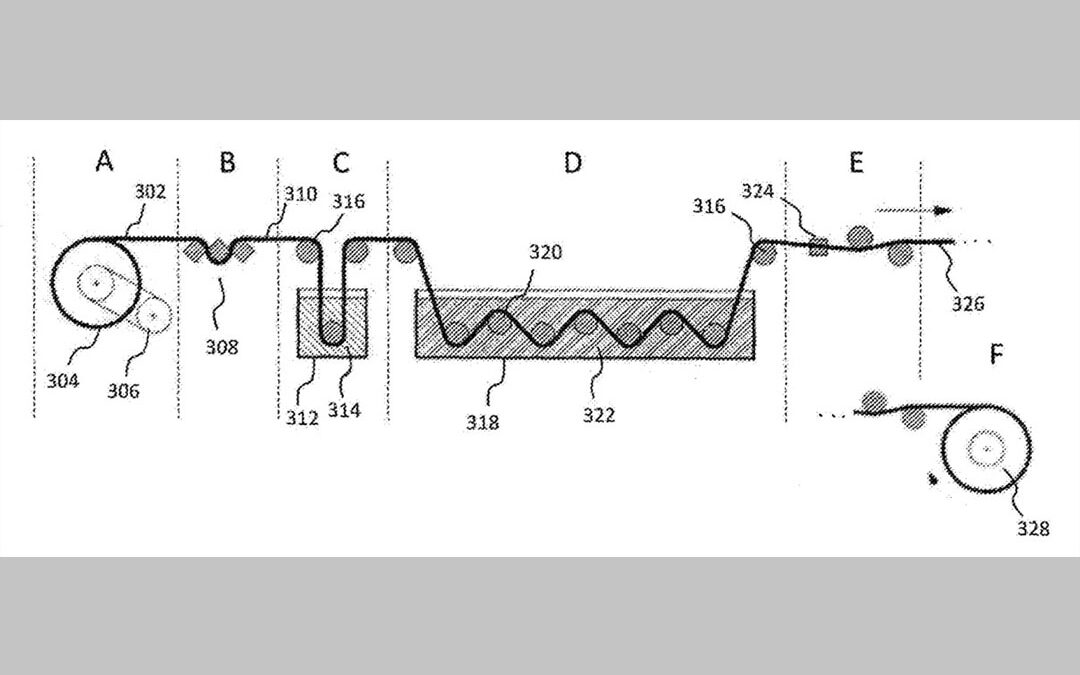

The invention relates to an apparatus and method for producing a cable made of filaments embedded in a binding material (322) containing the steps of spreading the filaments of a strand (302) of filaments to obtain a band (310) of filaments, wetting the surfaces of the filaments in the band (310), coating the surfaces of the wetted filaments in the band (310), shaping continuously the cross section of the band (310) for creating a cable containing filaments embedded in a matrix of binding material (322).

2021. July 8.

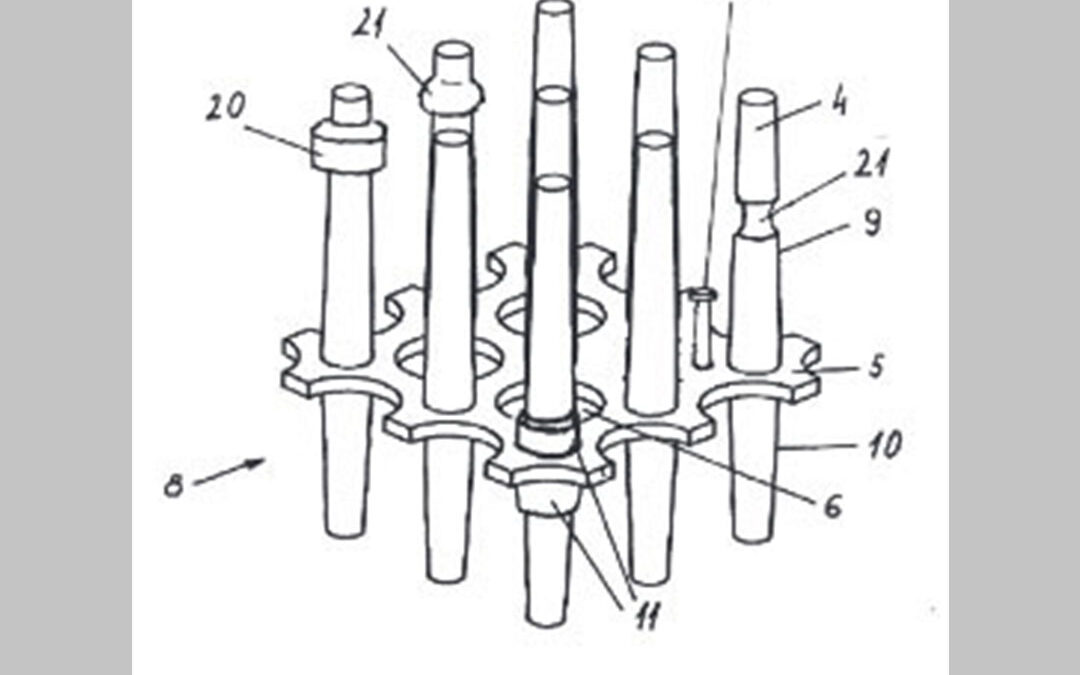

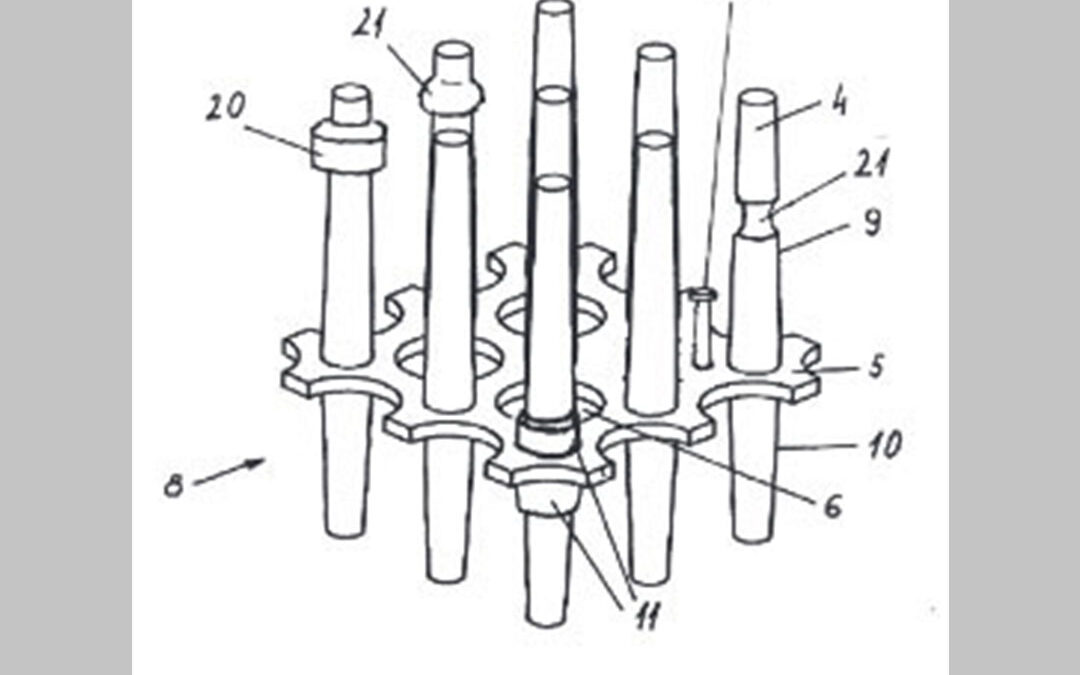

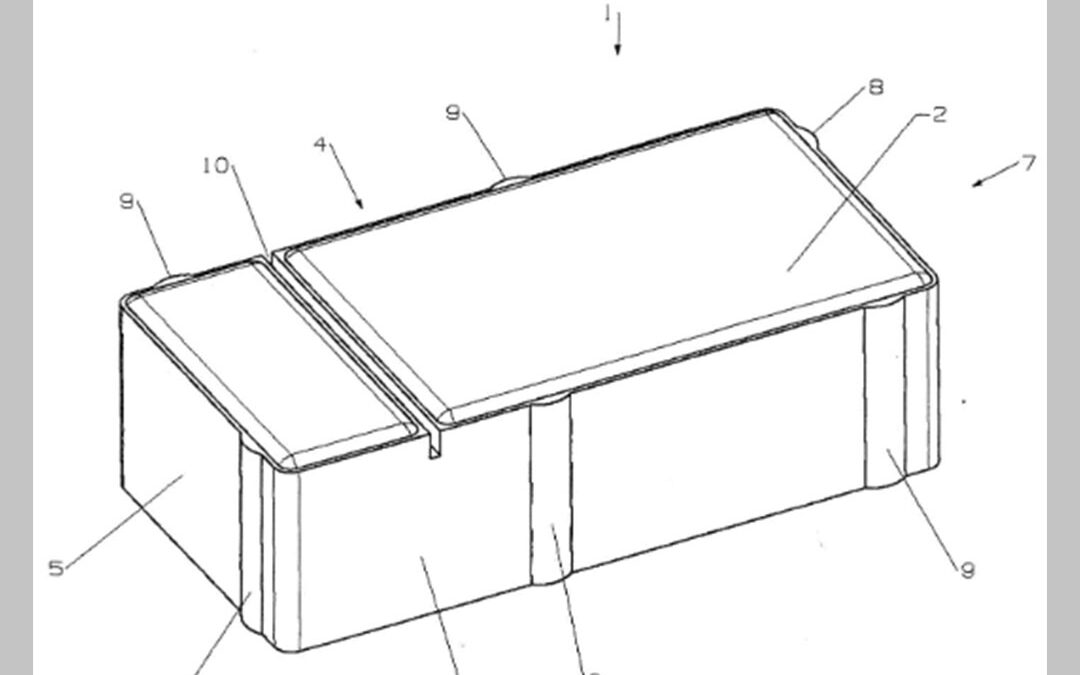

The invention relates to a translucent building block (1) having at least two, a first and a second bounding surfaces (2, 3), between which there is at least a part of a translucent member (4) and cast material surrounding said member (4) connected to an retainer structure (5), whereas the latter is arranged between said surfaces (2, 3). The invention also relates to a an insert (8) for producing a translucent building block (1) having an retainer structure (5) and at least one translucent member (4) arranged on said auxiliary retainer (5), and the translucent member (4) has at least one section (9, 10) projecting from said retainer structure (5), and said insert is provided with an opening formed on said retainer structure (5) and/or with a fixing member (19, 20, 21). The invention also discloses a method for producing a translucent building block (1).

2021. July 8.

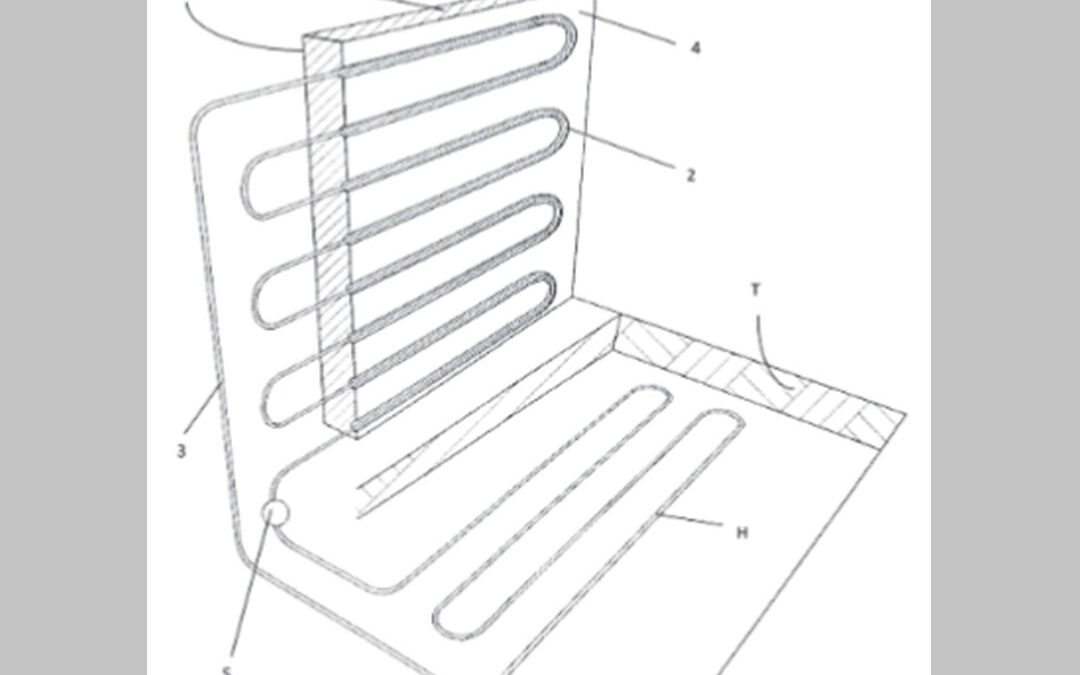

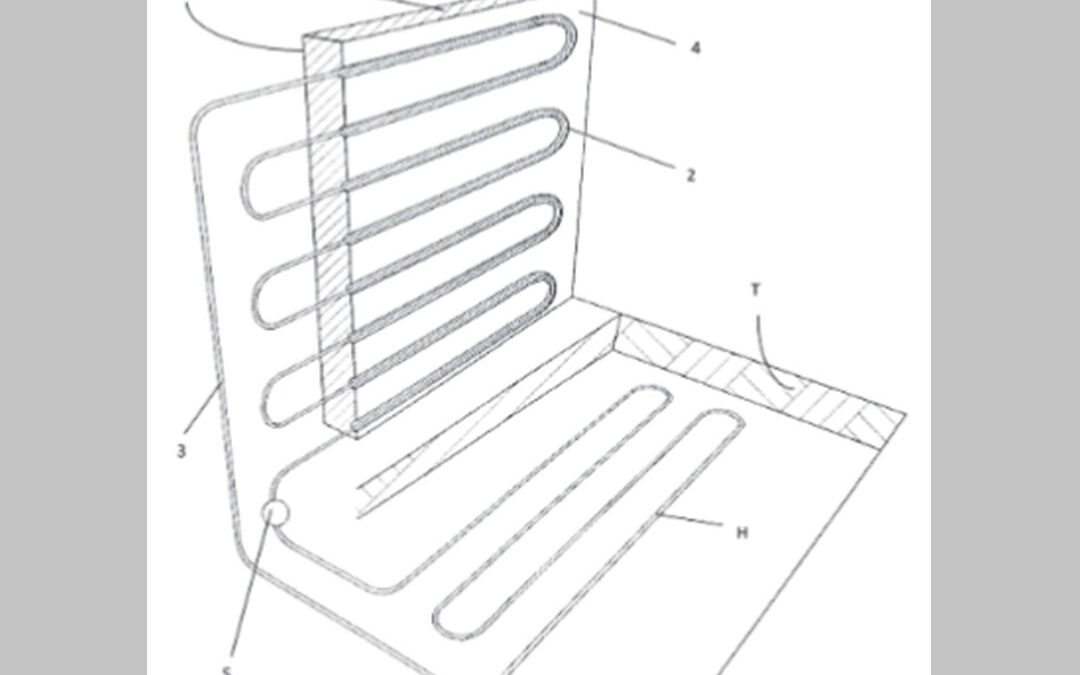

Apparatus for the active thermal insulation of external boundary structures of buildings, such as a wall structure (1), consisting of a pipe coil (3) fixed to the boundary structure, a heat exchanger connected to the pipe coil (3) and a heat exchanger medium circulating in the heat exchanger and the pipe coil (3). and is formed as a closed flow circuit 5) consisting of an expansion tank.

2021. July 8.

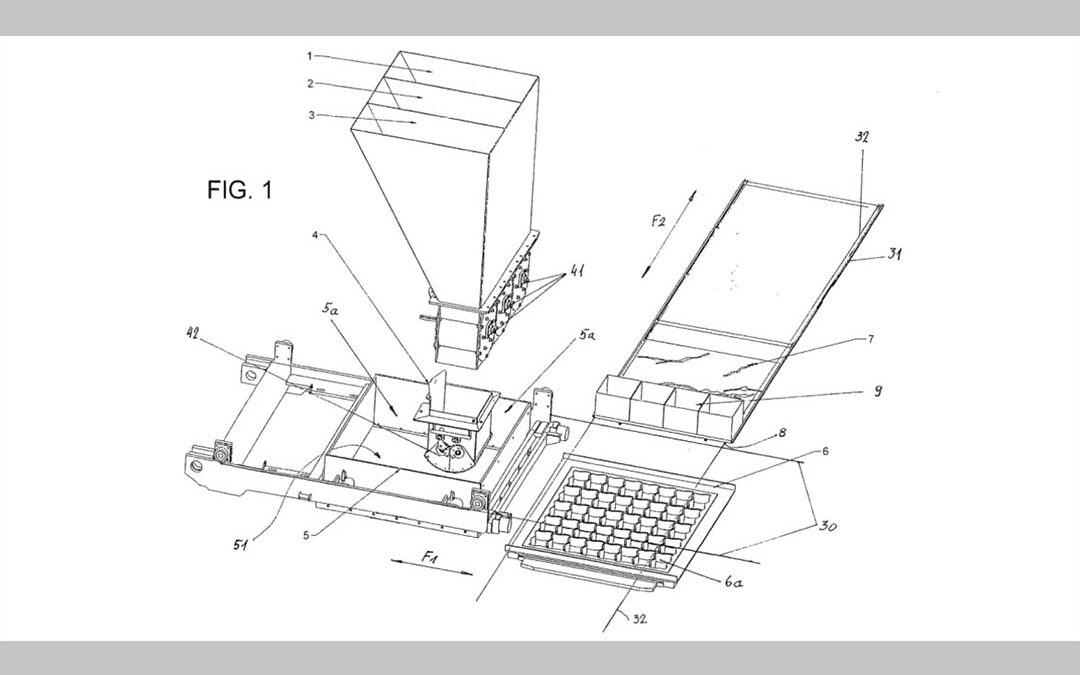

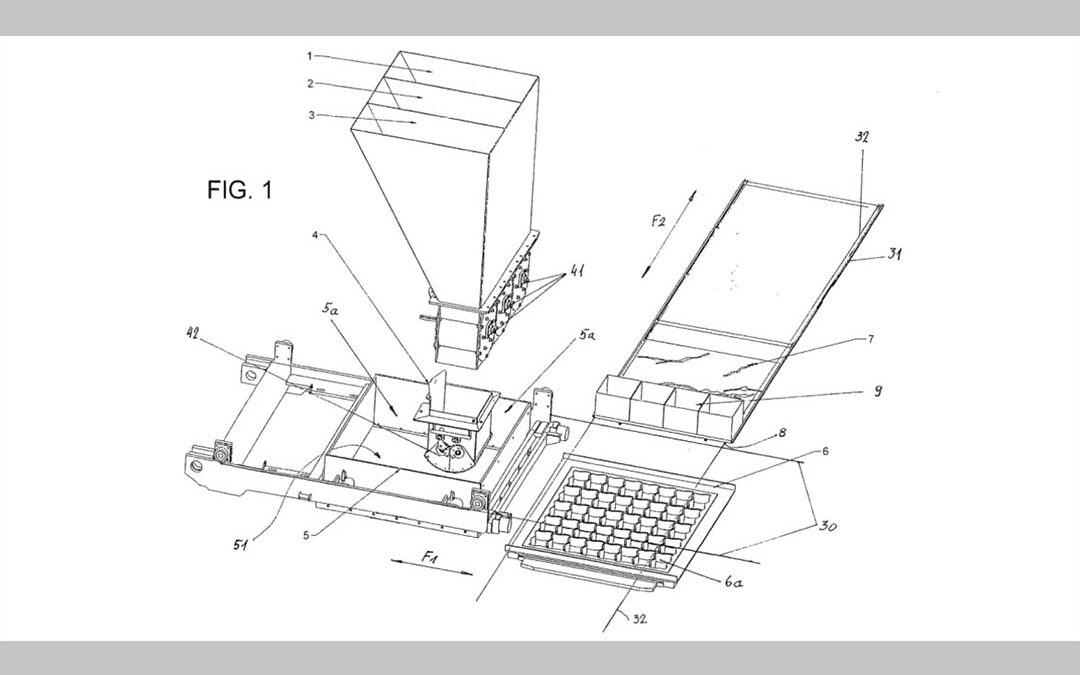

This invention relates to an apparatus and method for producing paver blocks (K) having ornamented, especially veined tread surface.

2021. July 8.

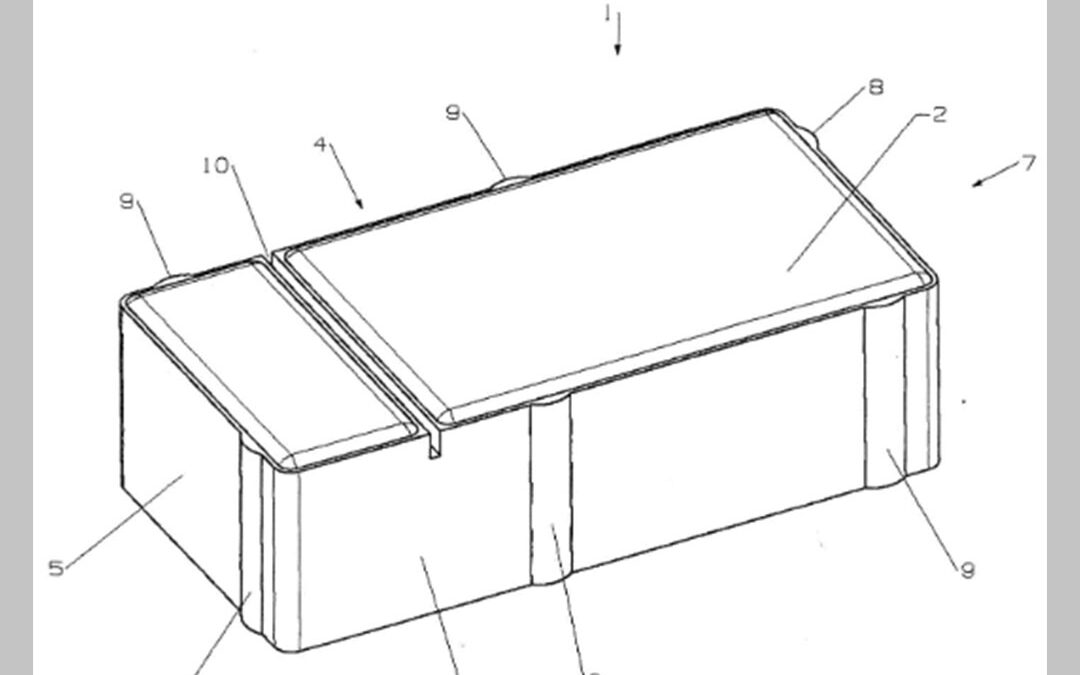

A cladding element (1) having a walking surface (2), a parallel base surface (3) and at least four side surfaces (4, 5, 6, 7) and a spacer element on at least two side surfaces (4, 5, 6, 7). 8, 9), characterized in that a groove (10) is formed in its walking surface (2) connecting its two side surfaces (4, 5, 6, 7) and having the same width (Sh) as the width (St) of the spacer.